| Cutting in (mm) | (TPI) TEETH PER INCH | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 10/14 | 8/12 | 6/10 | 5/8 | 4/6 | 3/4 | 2/3 | 1.4/2 | ||

| 0-20 | • | ||||||||

| 20-50 | • | ||||||||

| 25-60 | • | ||||||||

| 35-80 | • | ||||||||

| 50-100 | • | ||||||||

| 80-150 | • | ||||||||

| 120-350 | • | ||||||||

| 250-600 | • | ||||||||

Horizontal Band Saw TPI Chart

Always use the widest sawblade possible – the blade will be stronger and will withstand greater feed pressures. Blade tooth pitch is decided by the work piece and machinability. A minimum if two teeth should be in contact with the work. Coarse teeth are generally used for soft materials, fine teeth for hard materials and thin sections. The larger the workpiece the fewer the number of teeth per inch required.

The best surface finish is produced by fine tooth pitch, high saw speed and slow feed rate. Increased cutting rates are obtained by using a coarser tooth pitch, higher saw speed and faster rate of feed. Maximum Blade Life is achieved by selecting a medium pitch blade, slow saw speed and medium rate feed.

Please click on the Material you will be cutting from the list below. For advice on helping you find the correct blade please contact me at lee@altsawsandspares.com I am here to help!

To place an order please contact me at lee@altsawsandspares.com

Solid Material

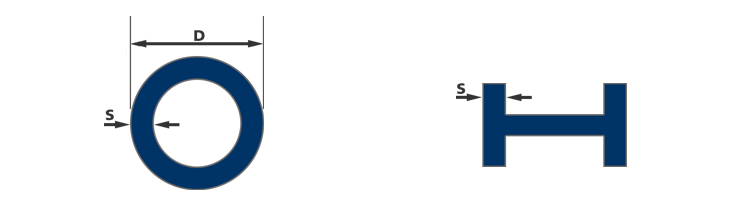

Tubes and Profiles

| (TPI) TEETH PER INCH | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| D (mm) | |||||||||

| S (mm) | 20 | 40 | 60 | 80 | 100 | 150 | 200 | 300 | 500 |

| 2 | 10/14 | 10/14 | 10/14 | 10/14 | 10/14 | 10/14 | 10/14 | 10/14 | 8/12 |

| 3 | 10/14 | 10/14 | 10/14 | 8/12 | 8/12 | 8/12 | 6/10 | 6/10 | 6/10 |

| 4 | 10/14 | 10/14 | 10/14 | 8/12 | 8/12 | 6/10 | 6/10 | 5/8 | 4/6 |

| 5 | 10/14 | 10/14 | 10/14 | 8/12 | 6/10 | 6/10 | 5/8 | 4/6 | 4/6 |

| 6 | 10/14 | 10/14 | 8/12 | 8/12 | 6/10 | 5/8 | 5/8 | 4/6 | 4/6 |

| 8 | 10/14 | 8/12 | 6/10 | 6/10 | 6/10 | 5/8 | 5/8 | 4/6 | 4/6 |

| 10 | 6/10 | 6/10 | 5/8 | 5/8 | 4/6 | 4/6 | 4/6 | 3/4 | |

| 12 | 6/10 | 5/8 | 4/6 | 4/6 | 4/6 | 4/6 | 3/4 | 3/4 | |

| 15 | 4/6 | 4/6 | 3/4 | 3/4 | 3/4 | 2/3 | |||

| 20 | 4/6 | 4/6 | 3/4 | 3/4 | 3/4 | 2/3 | |||

| 30 | 3/4 | 3/4 | 3/4 | 2/3 | 2/3 | 2/3 | |||

| 50 | 2/3 | 2/3 | 2/3 | 1,4/2 | |||||

| 75 | 2/3 | 1,4/2 | 1,4/2 | ||||||

| 100 | 1,4/2 | 1,4/2 | |||||||